Industrial Air Conditioning

Our industrial air conditioning systems are efficient and reliable, designed for large facilities and demanding working conditions, including in the mining industry. They provide effective cooling and optimal climate control in production halls, warehouses, mines, and office buildings. Characterized by high energy efficiency, quiet operation, and resistance to harsh conditions, which is crucial in the extraction industry, these systems also boast longevity that translates into lower operating costs. By choosing our industrial air conditioning, you opt for advanced technology, reliability, and comfort in every working environment, including challenging mining installations.

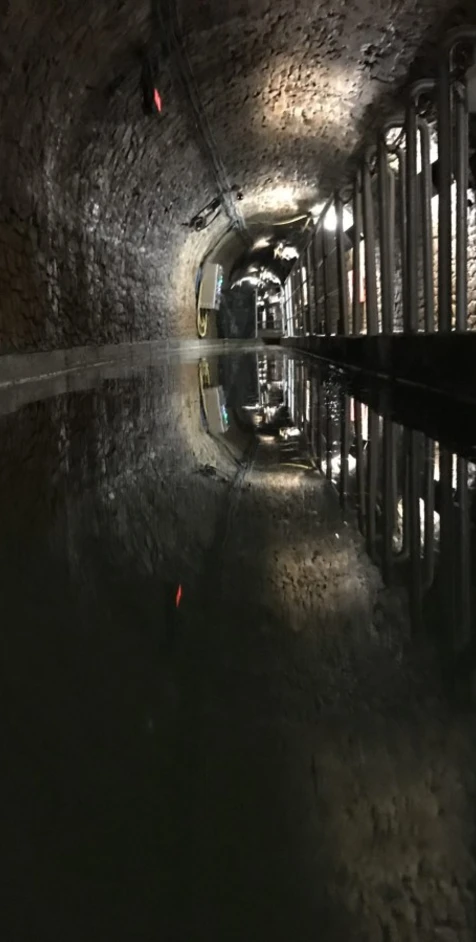

In addition to technical hazards arising from technological processes, there are also natural hazards related to the surrounding geological formations (water, gas, gas and rock emissions, gas and dust explosions, tremors, and climatic conditions).

Currently, in Poland, copper deposits are being exploited at depths of 1300 m, coal at levels from 850 to 1030 m, and potash salts in Belarus between 700 and 900 m. These conditions require the design of a ventilation and air conditioning system based on local conditions, the existing and planned cross-sections of mining excavations, the temperature of the surrounding rocks, the air flow rate, the number and size of operating machines and personnel at a given level and in a specific area, while considering the safety and comfort of the underground teams, as well as the temperature levels occurring locally at a specific humidity.

Polish mining regulations require employers employing workers underground to ensure a working temperature not exceeding 28 degrees Celsius, or if this is not possible, to shorten the working time of the crew to 6 hours. A temperature increase to 33 degrees is considered work under rescue conditions.

Ensuring stable microclimate parameters over time through ventilation and air conditioning of excavations is challenging to achieve but extremely necessary for the safe and efficient operation of mining crews.

Due to the fact that high-efficiency air conditioning systems with capacities ranging from several to several dozen megawatts are based on the production of chilled water in cooling machines, i.e., water at a temperature of approximately 2 degrees Celsius, it is necessary to consider the client's conditions regarding the possibility of locating the chillers in the Surface Air Conditioning Station. This involves delivering chilled water through a shaft and then through corridor excavations to the extraction areas and local headings, followed by the removal of absorbed heat and the discharge of heated water to the surface for heat release.

In this case, a necessary element is to reduce the pressure resulting from the depth of the shaft using heat exchangers or a Pelton turbine in order to minimize costs by recovering energy from the turbine.

If it is necessary to locate chillers in underground excavations, it is essential to adapt the roadway excavation by reconstructing it into an Underground Air Conditioning Station, from which pre-insulated (for chilled water) and non-insulated (for heated return water) pipeline networks distribute chilled water to the cooling-required extraction areas.

In this case, the location and discharge point of the heat are crucial for the efficiency of the air conditioning system. If we discharge warm water to the surface to use heat exchangers to capture thermal energy, this heat can be utilized, for example, for pre-heating water in the mine bath, and then, using a free cooling system, cooling towers, or air coolers, direct the water to reservoirs. After initial purification, it can be sent back through the shaft to the chilled water units.

Another important factor in planning industrial air conditioning installations is their durability, tightness, and the ability to regulate mass flows of water and energy depending on the local climatic conditions (temperature and humidity), external temperatures, and the season. It is also crucial to ensure resistance to scaling and contamination of the system by using the highest quality materials, including composite pipes, titanium heat exchangers, and efficient pumping systems that provide complete monitoring of pressures and flows, as well as the reading and regulation of set and actual temperatures.

Experienced engineers from our company will develop a conceptual and execution project for the air conditioning installation based on local and technical conditions, including calculations that take into account the necessary heat and cooling exchange, as well as the selection of locations and devices for cooling production, transmission, heat exchangers, control, and monitoring. This ensures that you can enjoy a functional installation for as long as possible.

We provide comprehensive customer service ranging from concept and design to delivery, installation, commissioning, operational support, and maintenance, including warranty work.

We have experience in implementing turnkey projects and technically demanding investment tasks, which involve teams of several hundred people.

By collaborating with us, you choose quality and professionalism, and we ensure that our clients return to us rather than just the product.

With a personalized approach to client projects, we ensure the optimal selection of machinery to maintain optimal working conditions with the lowest possible energy expenditure.

Thanks to our collaboration with partners such as CFT Polska and Korfmann, we are confident in the reliability of the solutions we offer.

We use titanium heat exchangers and complete automation of flows.

The composite pipelines we use for transporting chilled water ensure long-lasting performance, a lightweight design that facilitates installation, and resistance to dirt and scaling.